The DTF Gangsheet Builder is a revolutionary tool that transforms the way custom printing is approached, especially in the world of Direct-to-Film (DTF) transfers. This innovative software streamlines the gangsheeting process, allowing creators to maximize efficiency while achieving top-tier results in apparel printing techniques. If your aim is to enhance your output quality and reduce waste in your printing operations, understanding the DTF Gangsheet Builder is essential. In this guide, we will delve into effective gangsheeting tips, covering essential aspects such as design optimization, printer maintenance, and community collaboration. With the right approach to using this tool, you can elevate your custom printing endeavors and ensure the best possible results.

Introducing the DTF Gangsheet Builder opens up a myriad of possibilities for artists and businesses engaged in advanced printing methods. This tool is designed to optimize the direct-to-film process, which is increasingly popular for its efficiency in transferring multiple designs onto fabric. Utilizing gangsheeting techniques allows users to efficiently manage resources and enhance print quality, making it an indispensable asset in the sphere of custom apparel production. As you explore this topic, consider the various strategies and insights available, which can significantly enhance your understanding of DTF transfers and maximize your printing capabilities. Whether you are a seasoned professional or a newcomer to printing technology, mastering the DTF Gangsheet Builder can lead to remarkable advancements in your creative output.

Maximizing Efficiency with DTF Gangsheet Builder

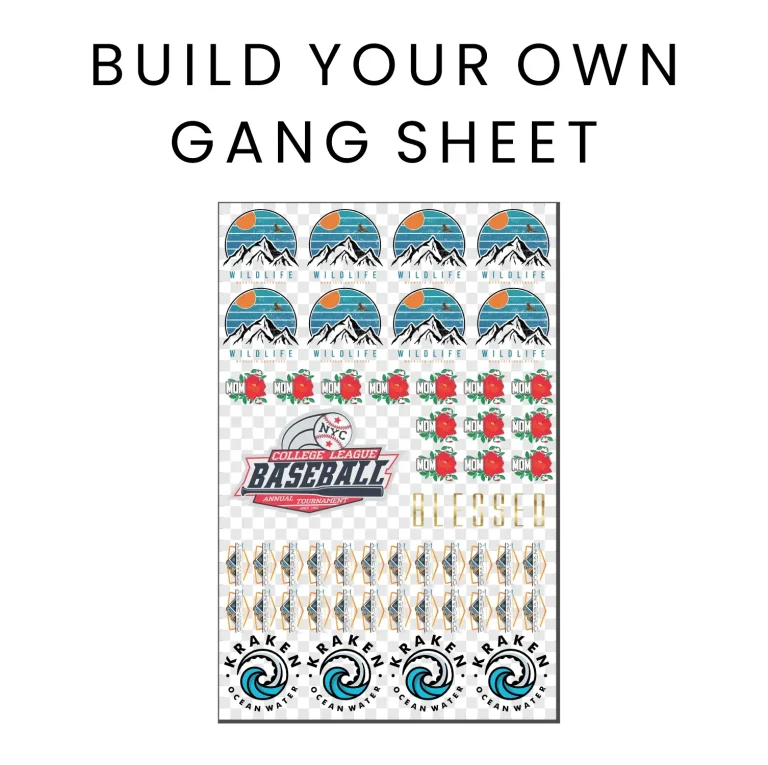

The DTF Gangsheet Builder is a game-changer for anyone involved in direct-to-film printing. This innovative tool allows you to combine multiple designs on a single sheet, which not only conserves materials but also significantly speeds up the printing process. By maximizing the output on each gangsheet, users can achieve higher efficiency, reducing turnaround times compared to traditional methods. Moreover, efficiency isn’t just about speed; it’s also about optimizing resource use, such as reducing ink wastage and lowering production costs.

As businesses look to balance quality and output, the DTF Gangsheet Builder stands out. When used correctly, it allows printers to capitalize on bulk printing advantages while maintaining the integrity of individual designs. Emphasizing a strategic layout on the gangsheet ensures that each design fits seamlessly, which is critical in both aesthetics and functionality in apparel printing. In turn, this increases customer satisfaction and promotes repeat business, elevating the overall profitability.

Essential Gangsheeting Tips for Beginners

For those new to gangsheeting, it’s essential to start with the basics. First, understanding the layout is pivotal; designs should be spaced evenly to prevent overlap that can cause issues during the transfer process. Beginners should consider utilizing software tools like Adobe Illustrator, which allow precise alignment and visualization before printing. Additionally, practicing with different layouts can help users discover the most efficient setups for their unique designs.

Another key tip for beginners is to perform test prints. Before committing to a full production run, conducting smaller test batches enables you to check for color fidelity and design placement. This practice can help identify potential pitfalls early on and allows adjustments without wasting materials. By learning to interpret test print results, new users can refine their skills in DTF printing and gain confidence in their gangsheeting techniques.

Choosing the Right Materials for DTF Printing

The success of a DTF print heavily relies on the materials used, particularly when selecting the right type of film or transfer paper. High-quality DTF film is essential; it directly impacts the durability and clarity of the final product. Low-quality materials can lead to issues such as peeling or fading, which ultimately detracts from the value of the printed apparel. Investing in reputable brands that specialize in DTF supplies is critical for achieving the best results.

Additionally, understanding the compatibility of your chosen materials with different fabrics is crucial in the apparel printing process. Certain films may adhere better to specific material types, which can affect the overall quality and longevity of the prints. For instance, cotton fabrics may require different settings or films compared to polyester blends. Therefore, conducting thorough research on the types of DTF transfers suited for your projects can enhance print performance and customer satisfaction.

Printer Settings Optimization for Superior Output

Getting the best results from your DTF Gangsheet Builder means nothing without properly optimized printer settings. Every printer has its specific operations, so adjusting ink saturation, temperature, and pressure can make a significant difference in print quality. As technology evolves, certain printers may offer features tailored for DTF printing, which can greatly enhance output. It’s essential to consult your printer’s manual for the recommended settings that apply specifically to DTF gangsheet printing.

Experimentation plays a vital role in finding the perfect printer settings. New users should take the time to conduct sample prints with various adjustments, noting how changes affect the final product. Signature issues such as ink bleeding or insufficient adhesion can often be traced back to improper settings. Adjusting factors like heat and duration of application time can lead to remarkable improvements and seamless designs that meet customer expectations.

Troubleshooting Common DTF Printing Issues

Understanding the common issues that arise during DTF printing is essential for anyone looking to succeed in custom apparel printing. Problems such as ghosting, inconsistent ink application, and color discrepancies often stem from improper setup, either in the software or printer configuration. Education about these pitfalls can empower users to diagnose problems quickly and develop effective solutions.

Moreover, regular maintenance and upkeep of printing equipment can drastically reduce occurrences of common printing issues. Scheduled cleanings, such as purging print heads and checking for clogged nozzles, are necessary practices that help maintain optimal printer performance. Staying proactive about troubleshooting not only saves time during production but also reinforces higher quality in every print, ultimately enhancing the reliability of your DTF printing endeavors.

Leveraging Community Resources for Knowledge and Support

Engaging with the DTF printing community provides invaluable resources for learning and troubleshooting. Online forums, social media groups, and dedicated platforms offer a wealth of knowledge where users share tips, tricks, and experiences. This community engagement is particularly beneficial for non-experts, as it fosters a collaborative environment where members can ask questions and receive guidance from more experienced professionals.

Additionally, participating in community discussions can lead to discovering new techniques and resources that may not have been previously considered. By learning from the collective experience of others, novice DTF printers can avoid common mistakes and streamline their educational journey. Leveraging these community insights accelerates growth in one’s capabilities, ultimately enhancing overall performance with the DTF Gangsheet Builder.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve DTF printing?

The DTF Gangsheet Builder is a specialized tool that streamlines the process of creating direct-to-film transfers for custom apparel. It allows users to efficiently arrange multiple designs on a single sheet, minimizing waste and reducing costs associated with DTF printing. By optimizing the layout and ensuring precise alignment, the builder enhances productivity and print quality.

What are some essential gangsheeting tips to maximize my DTF Gangsheet Builder’s efficiency?

To make the most of your DTF Gangsheet Builder, focus on optimizing your designs with adequate spacing, using grid lines for uniform alignment, and choosing the right color profiles for accurate color reproduction. Regularly checking your printer settings and maintaining your equipment can also prevent common issues and improve overall output in your DTF printing projects.

How do I choose the right software for use with my DTF Gangsheet Builder?

Selecting compatible software is crucial for the effective use of your DTF Gangsheet Builder. Popular options include Transfertape and Dingbats, which integrate well with graphic design tools like Adobe Illustrator and Photoshop. Using these applications allows for precise design creation and optimization, leading to high-quality DTF prints.

What materials should I use for the best results in DTF printing with the Gangsheet Builder?

Invest in high-quality DTF film that matches your printer type to ensure vibrancy and durability in your prints. Additionally, using premium papers recommended by industry sources can improve your results and meet your customers’ demands effectively in the custom printing market.

What printer settings should I adjust for optimal DTF printing results?

For the best output from your DTF Gangsheet Builder, adjust ink saturation levels and heat settings based on the fabric type you’re printing on. Always consult your printer’s manufacturer recommendations to find the optimal settings, which can vary between different printer models and materials.

How can online communities help improve my skills with the DTF Gangsheet Builder?

Engaging with online forums and groups dedicated to DTF printing allows for the exchange of experiences and solutions among users. These communities provide valuable insights and troubleshooting tips that can enhance your skills with the DTF Gangsheet Builder, helping you navigate common challenges effectively.

| Key Topic | Description |

|---|---|

| Understanding Gangsheeting | Combining multiple designs onto a single sheet to reduce waste and lower costs. |

| Benefits of Gangsheeting | Lower per-print costs and improved operational efficiency. |

| Compatible Software | Using software like Transfertape or Dingbats enhances the gangsheet building process. |

| Design Tips | Optimal design layout and color management for print fidelity. |

| Materials and Settings | High-quality film and optimized printer settings ensure better outcomes. |

| Regular Maintenance | Maintaining the printer enhances performance and consistency. |

| Common Issues | Awareness and adjustments regarding printing issues can improve results. |

| Community Resources | Engaging in forums provides valuable insights and troubleshooting support. |

Summary

The DTF Gangsheet Builder is a pivotal tool for optimizing the DTF printing process. Mastering its use involves a comprehensive understanding of gangsheeting—an efficient practice that combines various designs onto a single sheet. By leveraging compatible design software, employing strategic design tips, and ensuring high-quality materials, you can greatly enhance the efficacy of your printing projects. Furthermore, regular printer maintenance and an awareness of common printing issues can mitigate potential challenges, ensuring the perfect outcome every time. Engaging with community resources helps in building knowledge and accessing troubleshooting expertise. By implementing these strategies, users can ultimately elevate their quality and efficiency in the custom printing landscape, making the most of their DTF Gangsheet Builder.