UV DTF Transfers represent a remarkable advancement in custom printing technology, merging speed, quality, and versatility into one powerful solution. As this innovative technique allows for vibrant and durable prints on various materials, it is paving the way for a new era in personalized printing solutions. The benefits of UV printing are substantial, offering more than just aesthetic appeal; they include durability against fading and scratches that is essential for long-lasting products. Additionally, as businesses increasingly embrace print-on-demand capabilities, UV DTF transfers are becoming integral in meeting customer demands for custom, high-quality prints. With the rise of digital printing innovations, this technology stands out, positioning itself as a frontrunner in the evolving landscape of custom prints.

Within the realm of cutting-edge printing technologies, UV Direct-to-Film (DTF) transfers have emerged as a significant trend reshaping the market. Often referred to as state-of-the-art print solutions, this approach enables businesses to achieve personalized results that cater to unique consumer demands. These revolutionary printing methods utilize UV-curable inks that yield stunning finishes and impressive durability across various substrates, from textiles to rigid plastics. As more brands recognize the advantages of customized order fulfillment, including expedited production, the interest in formulating sustainable and innovative printing techniques continues to grow. Thus, UV DTF printing not only exemplifies the future of bespoke printing but also aligns perfectly with the trends of an increasingly personalized consumer landscape.

Understanding the Benefits of UV DTF Transfers

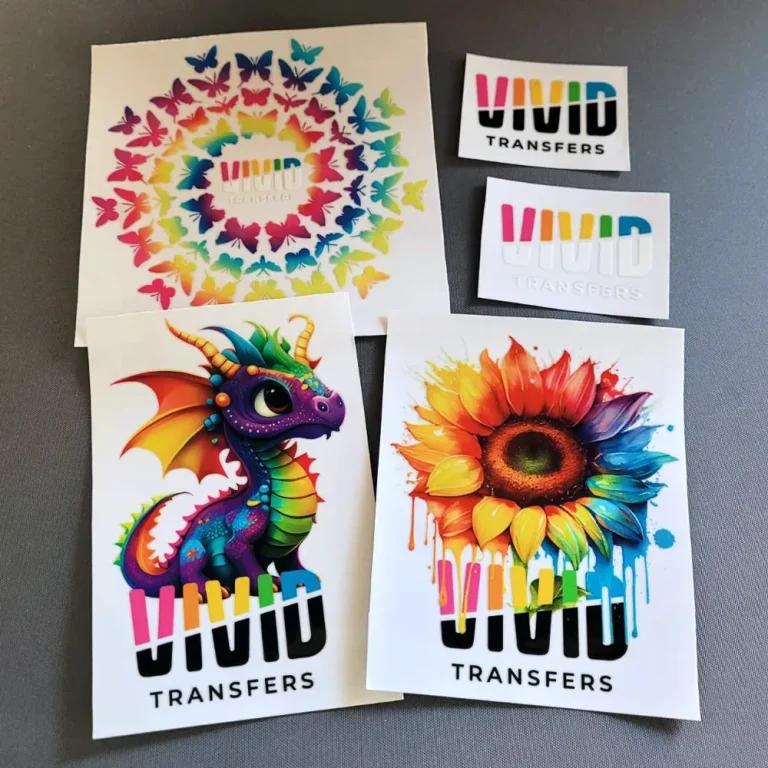

UV DTF transfers are gaining popularity in the printing industry due to their unparalleled ability to deliver vivid color saturation and intricate details. These prints excel in producing high-quality images that stand out, making them ideal for businesses focused on creating visually appealing products. Unlike traditional printing methods, which often struggle to achieve similar depth of color and detail, UV DTF printing utilizes advanced technology to ensure each print meets stringent quality standards, maximizing visual impact.

In addition to color vibrancy, durability is another significant advantage of UV Direct-to-Film printing. The UV-curable inks used in this process result in prints that are not only visually striking but also resistant to fading, scratches, and moisture. This durability is particularly vital for products exposed to the elements or subjected to frequent use. As a result, businesses can confidently offer customers prints that maintain their quality over time, reducing the need for replacements and enhancing customer satisfaction.

Frequently Asked Questions

What are the advantages of UV DTF Transfers over traditional printing methods?

UV DTF Transfers provide numerous advantages such as vibrant color reproduction, exceptional durability against fading and wear, and the ability to print on a wide variety of materials. These benefits make UV DTF Transfers a preferred choice for businesses seeking high-quality, personalized printing solutions.

How can UV DTF Transfers enhance personalized printing solutions for e-commerce businesses?

Using UV DTF Transfers, e-commerce businesses can offer customized products on demand with quick turnaround times. This technology allows these businesses to meet individual customer preferences seamlessly, thus enhancing their service offerings and customer satisfaction.

What is the potential market growth for UV DTF printing technology?

The UV DTF printing market is projected to exceed USD 5 billion by 2030, driven by increasing demand for high-quality and durable prints. This growth reflects the burgeoning interest in digital printing innovations that cater to various applications across industries.

Are UV DTF Transfers eco-friendly compared to other printing technologies?

Yes, UV DTF Transfers often incorporate sustainable inks and lower emissions, making them more eco-friendly than traditional printing methods. With the industry’s shift towards responsible practices, UV DTF technology supports businesses looking to implement greener printing solutions.

What materials can UV DTF Transfers be applied to effectively?

UV DTF Transfers are incredibly versatile and can be applied to a wide range of surfaces, including textiles, plastics, metals, and more. This compatibility opens new markets for creative applications, making it ideal for businesses in various sectors.

How does UV DTF Transfer technology contribute to faster production times?

UV DTF Transfer technology is designed to maximize efficiency, significantly reducing production times compared to traditional methods. The quick curing of UV inks enables companies to meet urgent client demands without compromising the quality of their custom prints.

| Key Points | Details |

|---|---|

| Understanding UV DTF Transfer Technology | Prints vibrant images on various substrates, offering versatility for different markets including textiles and signage. |

| Recent Developments in the UV DTF Market | Market expected to exceed USD 5 billion by 2030 due to demand for high-quality prints. |

| Advantages Over Traditional Printing | 1. Color Vibrancy 2. Durability 3. Eco-Friendly Practices |

| Technological Innovations | Enhanced curing methods and innovative ink formulations for a broader range of materials. |

| Future Trends in UV DTF Printing | Integration with e-commerce and expansion into diverse applications such as automotive and packaging. |

| Benefits Over Traditional Methods | Cost-effectiveness, faster production times, and greater material compatibility. |

Summary

UV DTF Transfers represent a transformative leap in the realm of custom printing, combining vibrant colors, durability, and adaptability across various substrates. As the demand for personalized products surges, UV DTF technology stands out due to its quick production capabilities and eco-friendly practices. This innovation not only enhances creativity and quality but also positions businesses ahead in an increasingly competitive market. Embracing UV DTF Transfers will undoubtedly empower manufacturers to meet and exceed the evolving expectations of consumers.