UV DTF transfers are revolutionizing the world of printing and design, offering creators a cutting-edge method to bring their artistic visions to life. This innovative technique harnesses the power of UV printing to produce vibrant, high-quality designs that can be applied to an array of surfaces, from textiles to hard materials. With the rise in DIY heat transfers, more individuals are looking for efficient yet effective printing techniques to enhance their projects. In this guide, we’ll delve into the essentials of UV DTF transfers, ensuring you have the knowledge and tools to create impressive and durable design transfers. Whether you are a beginner or a seasoned pro, mastering UV DTF will open up exciting possibilities for your creative endeavors.

When exploring ways to enhance your artwork, the realm of Direct to Film (DTF) printing techniques unveils a plethora of options for anyone passionate about design transfers. This method, often referred to as “DIY heat transfers,” stands out due to its versatility and effectiveness in producing high-resolution prints. The use of ultraviolet inks in DTF allows for unparalleled color vibrancy and longevity in your creations. As we dive deeper into this fascinating technique, you will learn how to leverage various printing methods to achieve stunning results that elevate your projects, whether for personal enrichment or small business ventures.

What Makes UV DTF Transfers Stand Out?

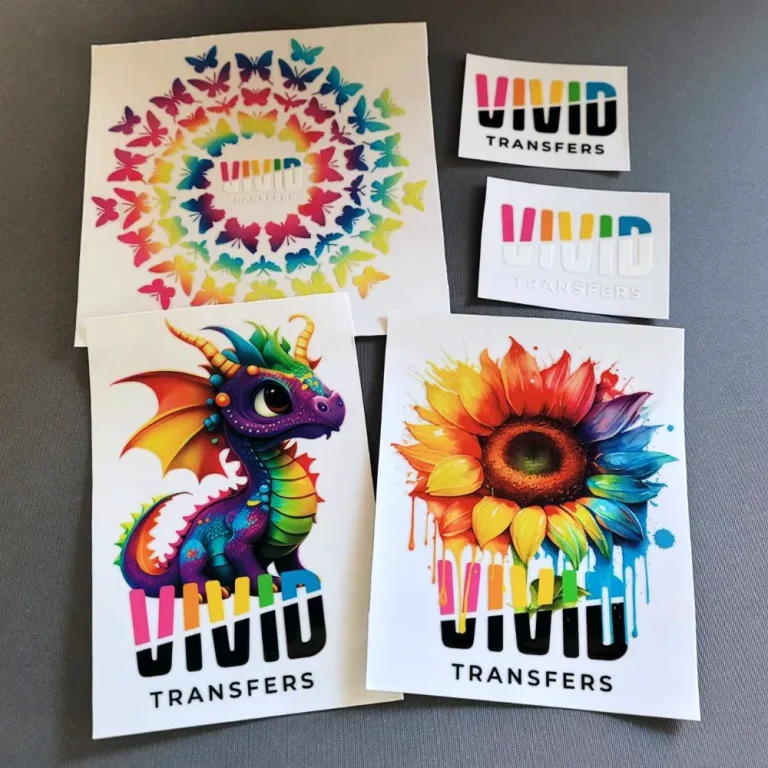

UV DTF transfers utilize cutting-edge technology that combines the efficiency of direct-to-film printing with the durability of ultraviolet inks. The process begins with high-resolution digital designs being printed directly onto a specially coated film using a UV printer. Unlike traditional screen printing, which can be labor-intensive and time-consuming, UV DTF transfers allow for quick production times, making them perfect for small businesses or DIY enthusiasts looking to create custom apparel or merchandise quickly.

One of the primary advantages of UV DTF transfers is their versatility. They can be applied to a wide variety of substrates, including textiles, wood, and even metal. This adaptability means that crafters and businesses can expand their product offerings beyond just clothing, providing endless creative possibilities. Additionally, the prints produced through UV DTF are not only vibrant in color but also possess excellent washability, ensuring that your stunning designs maintain their look even after many washes.

Furthermore, the curing process of UV inks helps produce designs that are resistant to fading, scratches, and peeling. The hardening of the inks under UV light creates a bond that withstands the test of time, making any product that features UV DTF transfers a worthwhile investment.

Overall, UV DTF transfers are an exciting option for anyone looking to enhance their crafting capabilities or small business offerings, merging quality, versatility, and efficiency.

Step-by-Step Guide to Creating UV DTF Transfers

Creating stunning designs using UV DTF transfers can be broken down into manageable steps, catering to both experienced and novice creators alike. First, it starts with the design creation phase, where graphic design software such as Adobe Illustrator or Canva is utilized to conceptualize visually appealing designs. It’s essential to use high-resolution images during this phase, as this ensures clarity and sharpness in the final transfer. The right choice of colors and design elements can significantly impact the overall look and feel of the finished product.

Once the design is finalized, proceed to print using a reliable UV DTF printer and high-quality DTF film. The quality of both the ink and film is crucial; low-grade materials can lead to poor adhesion and less vibrant prints. After printing, it’s important to cure the design using a UV light source properly. This step is vital because anything other than even curing may lead to improperly adhered designs that diminish the quality of your work.

The final steps involve the transfer process itself. By applying the cured film onto your chosen substrate with the application of heat and pressure, the design gets embedded securely into the fabric or material. It’s important to follow manufacturer instructions regarding the temperature and duration of pressing to ensure optimal results, ultimately leading to vibrant and high-quality design transfers that can impress customers and creators alike.

The Versatility of UV DTF Transfers Across Materials

One of the outstanding features of UV DTF transfers is their remarkable versatility. Unlike traditional printing methods that are often limited to textiles, UV DTF transfers allow creators to apply their designs to an assortment of materials, including wood, metal, and plastics. This opens up a plethora of opportunities for customization, enabling creators to think beyond just t-shirts and caps. Imagine the possibilities of creating stunning promotional items, personalized gifts, or unique home decor products with your custom designs.

Each substrate may require specific printing techniques and heat settings, but the ease with which UV DTF transfers can be adapted to suit various materials makes them an attractive choice for many. This adaptability allows for innovative projects where craftsmanship can shine, leading to unique offerings that stand out in a competitive market. Whether you’re a small business owner or a DIY enthusiast, the ability to use UV DTF transfers across multiple surfaces can significantly expand your creative horizons.

Durability and Quality in UV DTF Transfers

The durability of UV DTF transfers is one of the standout benefits of this innovative printing technique. UV-curable inks create a robust bond with the surface onto which they are applied, resulting in designs that not only appear vibrant but also exhibit exceptional resistance to wear and tear. Unlike traditional screen prints, which might fade or degrade over time, UV DTF transfers maintain their brightness and color integrity even after countless washes. This long-lasting quality is particularly appealing for businesses that seek to offer products their customers will cherish without constant worry about the integrity of the design.

Furthermore, the durability of UV DTF designs means they can withstand the rigors of everyday use, making them an excellent choice for items that will undergo frequent handling or washing. Be it apparel, home goods, or promotional items, UV DTF transfers exhibit resistance to scratching and peeling, ensuring your designs can hold up in various conditions. This assurance of quality can lead to increased customer satisfaction and repeat business, a critical aspect for anyone looking to monetize their creative endeavors.

Essential Tools for Successful UV DTF Transfers

To embark on your journey with UV DTF transfers successfully, being equipped with the right tools is essential. This begins with reliable graphic design software like Adobe Illustrator, which allows you to create stunning, customizable designs for various projects. Quality graphic design is the foundation of an impressive transfer, so having software that supports high-resolution outputs is indispensable. Additionally, investing in a high-quality UV DTF printer will ensure that your inks adhere properly and yield vibrant, detailed prints.

Other essential tools include high-quality DTF films, a UV curing machine or light source, and a heat press machine. Each of these tools plays a crucial role in the overall success of your UV DTF project. The heat press, for instance, is vital in ensuring proper adherence of your printed design to the substrate. Using precision instruments and maintaining consistent quality in your materials can dramatically influence the final output, allowing you to maximize the vibrant colors and intricate details that UV DTF printing can achieve.

Exploring New Trends in UV DTF Printing Techniques

As the crafting and printing landscapes continue to evolve, the advancements in UV DTF printing techniques present exciting new trends for creators. Innovations in UV curing technology and the introduction of eco-friendly ink options have allowed for even higher-quality prints with a lower environmental impact. Staying abreast of these developments can give you a competitive edge, enabling you to offer cutting-edge designs that appeal to environmentally conscious consumers.

Additionally, the rise of online communities sharing tips, tutorials, and inspirations means that getting up-to-date information and learning from others has never been easier. Platforms like Instagram and YouTube are filled with creative individuals who are eager to share their experiences and best practices. Engaging with these communities can foster new ideas, spark inspiration, and help you refine your UV DTF printing skills, allowing you to create unique, market-ready designs that capture attention.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers use a specialized printing technique that involves printing designs onto a DTF film with UV-curable inks. When exposed to ultraviolet light, the inks solidify, allowing for vibrant and durable designs that can be applied to various surfaces using heat and pressure.

What are the advantages of using UV DTF transfers compared to other printing methods?

UV DTF transfers offer several advantages, including increased versatility, as they can adhere to various substrates; improved durability, ensuring designs resist fading and peeling; and vibrant print quality, thanks to the broad color gamut achievable with UV inks.

Can I use UV DTF transfers on different materials?

Yes, UV DTF transfers can be applied to a wide range of materials beyond fabrics, including plastics, wood, and metals. This versatility makes UV DTF design transfers suitable for numerous creative projects.

How do I prepare my artwork for UV DTF printing?

To prepare your artwork for UV DTF printing, use graphic design software like Adobe Illustrator or Canva to create high-resolution images. Ensure that your designs meet the specifications for DTF film and are optimized for color vibrancy and detail.

What equipment do I need for UV DTF transfers?

To successfully create UV DTF transfers, you will need a UV DTF printer, high-quality DTF films, a UV curing machine, a heat press, and graphic design software. Having these tools will enable you to produce quality designs.

Is UV DTF printing suitable for beginners?

Yes, UV DTF printing is suitable for beginners due to its straightforward process and the accessibility of tools and tutorials available online. With practice and the proper equipment, anyone can create stunning designs using this technique.

| Key Step | Description |

|---|---|

| Design Creation | Conceptualize your design using graphic software, ensuring high-resolution images for clarity. |

| Printing the Design | Print on high-quality DTF film with a UV printer; select reliable equipment for best results. |

| Curing the Print | Cure the print with UV light, adhering to manufacturer guidelines for optimal exposure. |

| Transferring the Design | Use a heat press to apply the design on your chosen substrate, adjusting settings as needed. |

| Finishing Touches | Remove the film when cool and consider adding layers for enhanced durability against wear. |

Summary

UV DTF transfers offer a remarkable method for creators looking to produce stunning and durable designs effortlessly. This technique utilizes specialized UV-curable inks, allowing for vibrant prints that stand the test of time. By following a few simple steps—starting from design creation to the final application—anyone can master the art of UV DTF transfers. Whether you are a hobbyist crafting personalized items or a small business aiming to make a mark, embracing UV DTF transfers can enhance your creative projects and bring your visions to life effectively.