DTF Printing Essentials form the backbone of turning vibrant designs into durable transfers on textiles, delivering consistency and repeatable quality for every project. If you’re just starting out, understanding DTF supplies for beginners—what to buy, why it matters, and how much you should expect to invest—can save you time, money, and a lot of frustration, guesswork, and headaches in the early stages. In this guide, you’ll learn the must-have DTF transfer materials and how they interact with your printer, film, and powder, followed by a practical setup plan to move from concept to finished print that enables consistent results across runs and seasons. We’ll cover practical advice for the broader printer workflow, including selecting a machine that handles white ink, choosing compatible transfer film and powders, and designing with reliable color management. By the end, you’ll have a clear shopping list, a simple workflow, and the know-how to produce vibrant, durable transfers across a range of fabrics without detours, delays, or unnecessary confusion.

Viewed from another angle, this method is a film-to-fabric transfer system that uses pigment inks, a specialty release film, and a calibrated heat press to move color from film onto textiles. In LSI terms, it’s also described as direct-to-film printing, film-based garment transfer, or a color-rich textile printing workflow that centers on reliable materials and a repeatable process. The core idea remains simple: select compatible supplies, manage color accurately, and press with controlled temperature and timing for durable results. For beginners, focusing on a cohesive, scalable setup—printer, inks, films, powders, and a heat press—helps you grow into more advanced projects without starting from zero every time.

DTF Printing Essentials for Beginner Workflows: From Concept to Transfer

DTF Printing Essentials form the backbone of turning ideas into high-quality transfers onto textiles. For beginners, understanding what you truly need can save time, money, and a lot of frustration. In this context, DTF Printing Essentials means the core tools, materials, and workflows that make the process repeatable and predictable.

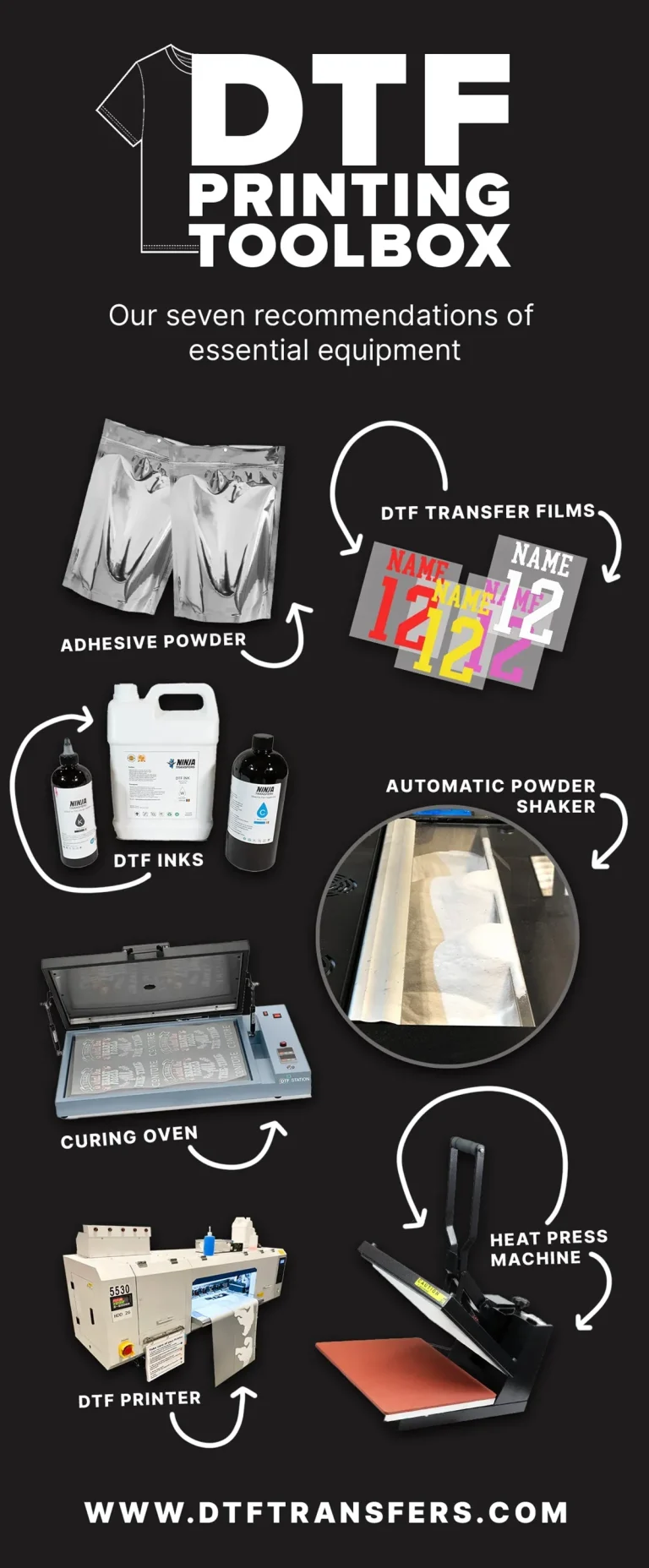

A practical beginner setup centers on a cohesive system: a printer capable of spraying white ink, a supply of transfer film, adhesive powder, a dependable heat press, and the right software to manage color. When these elements come together as part of your DTF printer setup and the selection of compatible DTF transfer materials, you can move from concept to finished product with fewer detours.

DTF Supplies for Beginners: Selecting a Starter Kit and Essential Tools

DTF Supplies for Beginners: Starting with a bundle from reputable vendors reduces compatibility headaches and wasted material. Look for a starter kit that pairs DTF transfer films, adhesive powders, and recommended inks to ensure the components work well together.

Beyond the bundle, evaluate the quality of each item, test on a few fabrics, and confirm that the kit supports your target substrates and color goals. This approach aligns with the idea of DTF supplies for beginners that set you up for predictable results.

DTF Printer Setup for Reliable Color and White Opacity

DTF Printer Setup for Reliable Color and White Opacity: Choose a printer designed for DTF that can handle white ink without frequent clogs and with solid color rendition. This is the heart of your workflow.

Develop a routine to install inks properly, run test prints, and calibrate color profiles for different fabrics. A consistent DTF printer setup reduces misalignment and builds confidence as you scale up.

DTF Transfer Materials: Film Quality, Edge Sharpness, and Color Fidelity

DTF Transfer Materials: Film Quality, Edge Sharpness, and Color Fidelity: The transfer film carries the design from the printer to the garment, so its thickness, release properties, and compatibility with the powder matter.

Pair the film with a compatible adhesive powder and adjust the air-to-heat settings to minimize edge fringing and ensure clean transfers. Testing several films helps you understand how edge artifacts affect the final image across fabrics.

DTF Inks and Powders: Achieving Opacity, Durability, and Color Management

DTF Inks and Powders: Achieving Opacity, Durability, and Color Management: The quality of the white and color inks determines opacity on dark fabrics.

Choose powders that distribute evenly and fuse reliably; invest time in color management and test prints to keep color accuracy consistent across batches. Understanding this pairing is essential for consistent results.

DTF Heat Press Tips and Best Practices for Durable Transfers

DTF Heat Press Tips and Best Practices for Durable Transfers: A good heat press delivers even temperature, uniform pressure, and controlled timing, all of which impact durability.

Use protective sheets, pre-press to remove moisture, and follow the film’s guidance for temperature and duration. After pressing, proper curing and post-press care help your transfers withstand washing and wear.

Frequently Asked Questions

In DTF Printing Essentials, what are the must-have DTF supplies for beginners and why do they matter?

DTF Printing Essentials for beginners rely on a core set of DTF supplies: a reliable DTF printer with white ink capability, compatible transfer film, adhesive powder, a dependable heat press, and a selection of substrates, plus basic cleaning and software. This cohesive kit helps you achieve opaque white areas, accurate color, and durable transfers that stand up to washing. By focusing on these DTF supplies for beginners, you can establish a repeatable, frustration-free workflow.

What are DTF transfer materials in the context of DTF Printing Essentials, and how do they affect image quality?

Within DTF Printing Essentials, selecting the right DTF transfer materials—film with consistent thickness, good release properties, and compatibility with your powders—directly impacts edge sharpness and color fidelity. A high-quality transfer film pairs with the adhesive powder to produce clean edges and vibrant images across fabrics. Poor film performance can introduce edge fringing and color drift.

What should be included in your DTF printer setup as part of DTF Printing Essentials for a smooth start?

Your DTF printer setup should ensure the machine can handle white ink reliably, with proper calibration, alignment checks, and color management. In DTF Printing Essentials, install inks correctly, configure drivers or RIP software, and run test prints to verify coverage and opacity before printing on garments.

What are the key DTF heat press tips within the DTF Printing Essentials framework to ensure consistent results?

DTF heat press tips include using even pressure and precise temperature control, pre-pressing to remove moisture, and protecting the design with silicone or Teflon sheets. In the DTF Printing Essentials approach, set the recommended temperature, time, and pressure per film guidelines, and monitor contact to avoid hotspots and uneven results.

How do DTF inks and powders fit into your DTF Printing Essentials kit, and how do they influence durability?

DTF inks and powders are central to durability and color density. In DTF Printing Essentials, choose high-quality inks for opaque whites and vivid colors, and apply a light, even powder coat for reliable adhesion. Proper curing and washing guidelines ensure the transfer remains vibrant after multiple cycles.

From DTF supplies for beginners to a finished transfer, what practical workflow does DTF Printing Essentials outline?

The workflow starts with choosing a starter kit, installing inks, and running test prints. Then prepare transfer film and apply adhesive powder evenly, pre-press the garment, and press with the recommended settings. Finally, follow post-press care and washing instructions to maximize durability.

| Key Point | Summary | Why It Matters |

|---|---|---|

| What is DTF Printing? | Direct-to-film (DTF) printing uses a modified ink system, transfer film, and heat press to move ink from film to fabric, enabling full-color designs on textiles with a forgiving workflow. | Foundation for beginners to understand the process and expectations. |

| System mindset | DTF setup is a cohesive system, not a single gadget; requires a printer with white ink capability, transfer film, adhesive powder, a heat press, substrates, software, and safe handling practices. | Ensures consistency and repeatability. |

| DTF printer & inks | Reliable DTF printer with dependable white ink capability, good color rendition, and stable maintenance; pair with high-quality DTF inks. | Enables vivid, opaque designs on darker fabrics. |

| DTF transfer film | Film with consistent thickness, excellent release properties, and compatibility with transfer powder. | Affects image sharpness, color fidelity, and predictability. |

| DTF adhesive powder | Powder that distributes evenly and fuses cleanly; creates durable transfers after washing. | Critical for adhesion and wash durability. |

| A heat press | Even pressure, stable temperature, reliable time control; adjustable up to ~200°C; use protective sheets. | Ensures consistent transfer quality and protects designs. |

| Protective consumables & basics | Lint-free cloths, isopropyl alcohol, lint rollers, storage, and Teflon/silicone sheets; safeguards transfer and garment. | Supports consistency and longevity. |

| Substrates & apparel | Start with reliable blanks; test on cotton and cotton blends; also test poly blends and dark fabrics. | Determines color vibrancy and durability across fabrics. |

| Cleaning & maintenance | Regular cleaning of print head and equipment; maintain a schedule to prevent buildup. | Prevents clogs and extends printer life. |

| Software & color management | RIP software or drivers with color management; create print profiles for fabrics and films. | Crucial for consistent color across batches. |

| Practical workflow steps | 1) Choose a starter kit; 2) Set up printer and test print; 3) Prepare film and powder; 4) Pre-press garment; 5) Press with precision; 6) Post-press handling; 7) Post-print care. | Provides a repeatable process from idea to finished print. |

| Common beginner pitfalls | Inconsistent color/opacity; fading after washing; sticky transfers; film jams; maintenance issues. | Addressed by testing, proper profiles, powder, pre-press, and regular cleaning. |

| DTF vs other methods | DTF offers versatility and high color density, especially on dark fabrics; compared to sublimation, screen printing, and DTG. | Helps decide when DTF is the right choice given costs and workflow. |

| Maintenance, care, and ongoing improvements | Regular upkeep, refine workflow, experiment, seek feedback, and optimize inks, films, and powders for different fabrics. | Keeps quality high and efficiency improving over time. |

Summary

DTF Printing Essentials for beginners establish a clear, repeatable path from idea to durable, high-quality transfers. Start with core tools—DTF printer with compatible inks, transfer film, adhesive powder, a dependable heat press, and a simple workflow for garment preparation, pressing, and care. As you gain experience, you’ll add refinements such as advanced color management, better substrates, and more efficient post-press handling. Stay curious, test frequently, and document your results. With the right essentials in place and a steady practice routine, you’ll transform ideas into vibrant, durable prints that stand out in the market. The world of DTF printing is accessible to beginners who commit to a thoughtful setup, continuous learning, and quality. Your journey from novice to proficient printer starts with the essentials—and your first successful transfer could be just one test run away.