UV DTF transfers have emerged as a versatile solution for elevating apparel, accessories, and home decor with vibrant color, crisp detail, and durable adhesion across a wide range of substrates, enabling brands to expand on-demand customization without sacrificing finish quality. In particular, UV DTF case studies demonstrate how designers leverage rapid curing and strong color fidelity to support limited drops, regional campaigns, and premium-packaging concepts that resonate with today’s digitally connected shoppers. When weighing options, evaluating color fidelity, cure speed, and substrate compatibility helps teams choose the path that best matches creative intent and production constraints. If you’re looking for practical steps on how to apply UV DTF transfers, this guide breaks down the exact workflow—from high-resolution design and pre-press prep to printing, curing, transfer setup, and post-press checks. Together, these insights emphasize reliability, color consistency, and efficient production, helping brands scale with confidence as consumer demand for personalized items continues to grow.

From an SEO and semantic-clarity perspective, UV-curable direct-to-film transfers describe the same technology as UV DTF, but framed with terms that highlight the chemistry and the film-based workflow. This framing emphasizes the UV-curing step, the film substrate, and the transfer mechanism, clarifying how designers achieve photo-quality detail on textiles, leather, glass, and even some plastics. Other LSI-ready phrases—digital textile transfers, UV-cured film prints, on-demand customization, and premium finishes—help readers associate the concept with practical applications in fashion, home decor, and packaging. By focusing on outcomes like fast setup, batch consistency, strong wash resistance, and broad substrate compatibility, the narrative aligns with search intents while remaining informative and accessible.

Unlocking UV DTF transfers: ideas, case studies, and practical steps

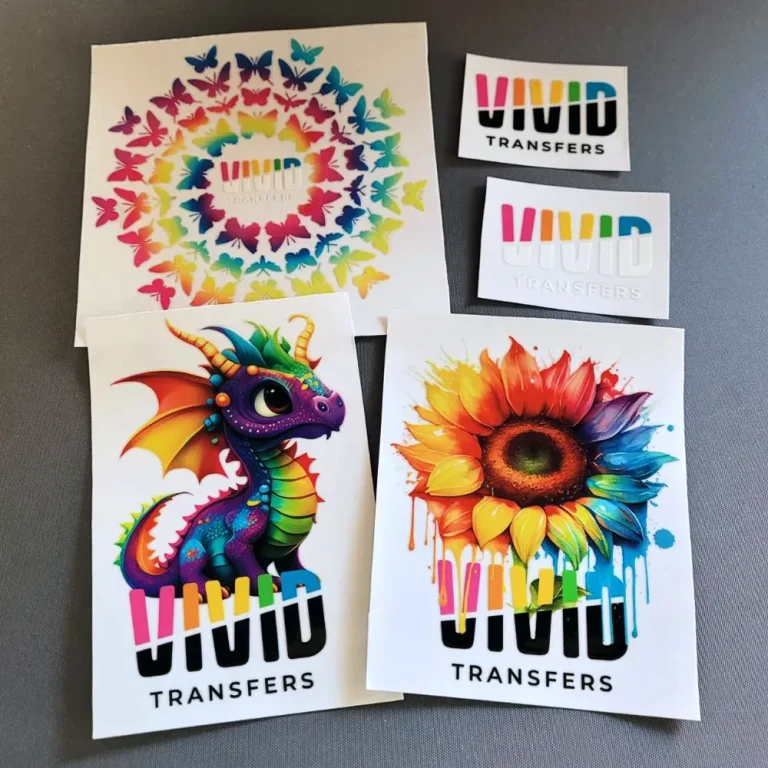

UV DTF transfers combine the precision of digital design with durable heat-applied finishes, delivering vibrant color, sharp edges, and strong adhesion across substrates from cotton blends to leather and certain hard surfaces. This versatility makes it possible to elevate product lines in apparel, accessories, and home decor without sacrificing production efficiency.

This technology supports on-demand customization and limited drops, allowing brands to test concepts quickly and measure impact through real-time sales signals. By integrating UV DTF transfers into your workflow, teams can move from concept to market faster while maintaining premium print quality and consistent results.

UV DTF transfer ideas to diversify products across apparel, home decor, and accessories

UV DTF transfer ideas span custom apparel, accessories, and small home goods, letting brands extend their pattern library into bags, hats, cushions, and gift items. The fidelity of UV DTF transfers enables bold graphics and high-contrast images across multiple product categories.

Here are UV DTF transfer ideas you can start with, such as name personalization, local landmarks, or bold graphic motifs for limited-edition runs. These concepts leverage rapid production and strong color fidelity to create premium items that resonate with customers.

UV DTF case studies: real-world results that shape strategy

Case Study 1 highlights an independent streetwear label that used UV DTF transfers to launch a limited-edition capsule. The initiative yielded a 28% lift in online sales and a 15% increase in average order value, while prints remained durable through wear-and-wash testing. This example demonstrates how UV DTF transfers can boost perceived value and drive early momentum.

Case Study 2 follows a home decor and accessories brand that applied UV DTF transfers to cushion covers, tote bags, and phone sleeves. The brand reported more vibrant color reproduction, better batch consistency, and faster restock cycles due to rapid setup and shorter lead times, contributing to a 22% year-over-year revenue rise and stronger repeat purchases. These UV DTF case studies illustrate the strategic benefits across categories.

DTF transfers vs UV: understanding the performance, durability, and substrate scope

DTF transfers vs UV require considering key differences in color, curing, and substrate compatibility. UV curing typically delivers brighter whites and crisper lines on a broader range of fabrics, particularly darker backgrounds, while speeding up production with rapid cure times.

When deciding between UV DTF and conventional DTF, evaluate substrate compatibility, desired turnaround speed, and the need for non-fabric applications. This comparison helps brands tailor sourcing, select appropriate presses and films, and size runs to balance quality with cost.

How to apply UV DTF transfers: a practical workflow and tips

How to apply UV DTF transfers starts with design preparation, ensuring high-resolution artwork and clean color separations suitable for the transfer process. Pay attention to white ink handling for designs that require white on colored substrates, and prepare vector elements for sharp, scalable edges.

The workflow continues with substrate preparation, printing and UV curing, transfer setup, and post-press handling. Following a structured process and performing quality checks—such as edge integrity and color stability—helps ensure durable adhesion and consistent results across batches.

Best practices UV DTF transfers: color accuracy, prep, and quality controls

Best practices UV DTF transfers emphasize high-quality designs, proper color calibration, and consistent heat and pressure across all transfers to maximize color fidelity and adhesion. Establishing a repeatable color workflow helps preserve vibrancy across substrates and batches.

Additionally, implement pre-testing on representative samples, consider finishing options like soft-touch coatings or protective coatings for added durability, and define simple quality metrics for abrasion resistance and colorfastness to minimize returns and ensure reliable performance.

Frequently Asked Questions

DTF transfers vs UV: How do UV DTF transfers compare to traditional DTF transfers?

UV DTF transfers use UV-curable inks to deliver brighter whites, crisper lines, and faster curing, resulting in vibrant color fidelity on many fabrics and substrates. By contrast, traditional DTF relies on heat-curing inks, which can have different color stability and substrate limitations. When choosing between them, consider your substrate mix, required turn times, and the desired durability of the finish.

How to apply UV DTF transfers: what are the practical steps and what substrates work best?

Follow a clear workflow: design preparation, substrate prep, printing and UV curing, transfer setup, post-press handling, and quality checks. UV DTF transfers work well on cotton, blends, leather, glass, and certain plastics, but always test compatibility with your heat-press and film system. Consistent dwell time, temperature, and pressure are key to durable adhesion.

What are the best practices UV DTF transfers? Tips for color, curing, and adhesion.

Use high-resolution designs sized for the transfer, calibrate your color workflow for UV DTF, and pre-test on representative samples. Maintain consistent heat and pressure, verify white ink handling when required, and consider finishing options like protective coatings for added durability.

Can you share UV DTF case studies: how two brands elevated their lines with UV DTF transfers?

Case Study 1 (indie streetwear) shows a limited-edition capsule with high-contrast designs printing well on dark fabrics, achieving a 28% lift in online sales and 15% higher average order value, with durable wear-and-wash performance. Case Study 2 (home decor and accessories) reports more vibrant color, faster restock cycles, a 22% year-over-year revenue increase, and stronger repeat customers due to premium finishes.

What UV DTF transfer ideas can help elevate product lines for apparel, home decor, and packaging?

Ideas include: 1) custom apparel and accessories with names or unique art; 2) limited-edition home accents like cushions and lampshades; 3) branded packaging and gift sets; 4) interactive collaborations with artists; 5) outdoor-friendly products if substrates allow.

What are common challenges with UV DTF transfers and how to troubleshoot them?

Common issues include edge cracking, color bleeding, and uneven adhesion. Solutions: adjust pre-press times, verify temperature and dwell time, ensure even pressure, test substrate compatibility, and confirm proper curing for durability.

| Topic | Key Points |

|---|---|

| What are UV DTF transfers? |

|

| Why brands consider UV DTF transfers |

|

| Case studies: how two brands elevated their lines |

|

| Creative ideas to elevate your product line |

|

| How to apply UV DTF transfers: steps |

|

| DTF transfers vs UV: quick comparison |

|

| Best practices for UV DTF transfers |

|

| Troubleshooting common challenges |

|

Summary

Conclusion: UV DTF transfers offer designers and brands a versatile path to vibrant, durable finishes with flexible production. By leveraging real-world case studies, exploring diverse transfer ideas, and following practical application steps, you can elevate your product line with confidence. Whether launching a limited-edition capsule, expanding into home decor, or offering customized items, UV DTF transfers deliver a compelling blend of quality, speed, and customization aligned with modern consumer expectations for premium, personalized products.