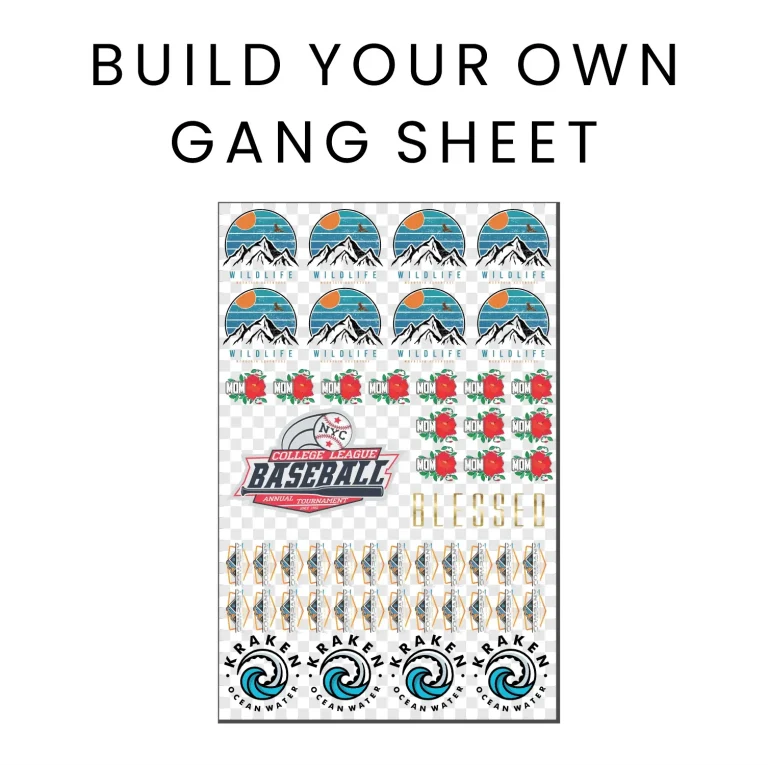

In the dynamic realm of custom apparel printing, the **DTF Gangsheet Builder** stands out as a revolutionary tool that streamlines the DTF (Direct-to-Film) transfer process. Offering an efficient approach to design optimization, this software empowers users to arrange multiple graphics on a single sheet, maximizing material usage and cutting costs. With its user-friendly interface, you can easily configure print settings for DTF to achieve vibrant, high-quality outputs on various fabrics. This guide will immerse you in the essentials of using the DTF Gangsheet Builder, guiding you from design preparation to the final print. Embrace this technology to elevate your custom apparel projects and minimize waste like never before.

The **Gangsheet Builder software** is a vital resource for anyone involved in DTF printing, revolutionizing how designs are applied to textiles. By allowing users to compile multiple images onto a single transfer sheet, it enhances productivity and efficiency in custom apparel creation. This innovative tool empowers artists and small business owners to reduce costs while ensuring high-quality results in their DTF transfer projects. Understanding the DTF printing process and utilizing the right print settings can make all the difference in achieving long-lasting and vibrant designs. In this article, we will delve deep into the features and advantages of the DTF Gangsheet Builder, helping you unlock its full potential.

What is DTF Printing and Why It Matters?

DTF (Direct-to-Film) printing represents a transformative leap in the realm of custom apparel printing. This innovative method replaces traditional printing techniques by providing a streamlined process that enables the transfer of vibrant designs onto fabric. Utilizing specialized inks, DTF prints offer high-quality images that retain their color and integrity longer than many conventional methods. This ability to produce eye-catching and durable prints makes DTF printing a preferred choice for small businesses and individuals alike, helping them to create products that stand out.

One of the standout features of DTF printing is its versatility. With the DTF transfer process, users can apply detailed designs on a variety of fabrics, including cotton, polyester, and blends. This adaptability is crucial for those looking to meet diverse customer demands. Furthermore, it’s not just the print quality that matters; the process also minimizes waste, as transfers can be tiled and arranged to make the best use of materials. Consequently, the DTF technique is not just about aesthetics but also about sustainability, making it an appealing option in today’s conscious consumer market.

Unlocking the Power of the DTF Gangsheet Builder

The DTF Gangsheet Builder is a game-changing tool designed to help users maximize productivity and reduce waste in the printing process. By allowing multiple designs to be fitted onto a single transfer sheet, this software significantly cuts down on the amount of DTF film and ink used, making it a cost-effective solution for custom apparel printing. For designers and print shops, this means more efficiency and less material cost, allowing them to focus on creativity and customer satisfaction.

Understanding how to effectively use the DTF Gangsheet Builder can drastically enhance the quality of prints and the overall workflow. With this tool, designers can easily arrange their images to optimize space, ensuring that every print is utilized to its fullest potential. Additionally, many Gangsheet Builder software options integrate smoothly with the print settings for DTF, allowing users to customize their output for their specific printer models, further enhancing the flexibility and quality of the final products.

Step-by-Step Guide to Using the DTF Gangsheet Builder

Mastering the DTF Gangsheet Builder requires a clear understanding of its interface and capabilities. Start by preparing high-resolution images that are ideal for your intended designs. Once the artwork is ready, importing it into the Gangsheet Builder is straightforward, allowing users to easily drag and drop their images. A well-organized workspace within the software ensures that you can view all designs simultaneously, helping you make the best decisions regarding image arrangement and sizing.

After loading your images, the next essential step is to configure the print settings for DTF accurately. This includes selecting the appropriate DPI, ensuring that your color profiles match the materials you are using, and adjusting other critical settings such as the ink type and transfer temperature. By paying attention to these details while using the Gangsheet Builder, you can achieve vibrant colors and crisp images that stand the test of time.

Key Print Settings for Success in DTF

One of the pivotal aspects of achieving stunning prints in DTF printing lies in understanding and optimizing your print settings. Setting the correct DPI is crucial for ensuring high-resolution outputs that are clear and vibrant. Typically, a DPI setting between 300 and 600 is recommended, as it strikes a balance between detail and print speed. Furthermore, choosing the right color profiles tailored to your specific printer will enhance the color output, guaranteeing that the final product reflects your original design intentions.

Beyond DPI and color profiles, another vital setting is the type of ink used during the printing process. DTF printing requires specially formulated inks that bond well with the film and fabric. Ensuring your printer is calibrated and that the print bed is clean can prevent issues such as smudging or color misalignment. By carefully adjusting these print settings, you can significantly elevate the quality of your DTF prints, allowing your custom apparel to shine in a competitive marketplace.

Troubleshooting Common Issues in DTF Printing

Despite the advantages that DTF printing provides, users may occasionally encounter challenges that can affect the quality of their prints. Common issues include problems with ink adhesion, unexpected color discrepancies, or complications related to the application of the transfer. For instance, if prints are peeling or cracking, it may indicate that the heat press settings were not dialed in correctly. Therefore, it’s crucial to meticulously follow the recommended temperature and pressure guidelines during application.

Engaging with the DTF printing community, whether through forums or social media groups, can provide invaluable insights into overcoming these common obstacles. Many experienced users share their troubleshooting techniques and tips, which can help newcomers navigate the complexities of DTF printing more effectively. By learning from shared experiences and solutions, you can enhance your problem-solving skills and boost the overall success of your custom apparel business.

Learning Resources for DTF Gangsheet Builder Mastery

To master the DTF Gangsheet Builder effectively, leveraging available resources is essential. Numerous online platforms offer tutorials, videos, and articles dedicated to the nuances of DTF printing and gangsheet creation. Websites like YouTube feature an abundance of visual guides that cover everything from beginner basics to advanced techniques, helping users visualize the steps involved. Furthermore, community-driven sites like Printful and Transfer Express provide actionable tips, software recommendations, and industry insights tailored to DTF printing.

Additionally, many education-focused platforms offer in-depth courses on DTF printing, helping aspiring professionals understand both the artistic and technical aspects of the process. These resources often delve deep into topics such as color management, design strategies, and equipment optimization which are crucial for successful custom apparel printing. By continually educating yourself through these channels, you can hone your skills and remain competitive in a rapidly evolving industry.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized software tool used in the DTF printing process that allows users to efficiently arrange multiple designs on a single transfer sheet. This maximizes material usage and reduces costs, making it ideal for custom apparel printing. By using the Gangsheet Builder, you can optimize your designs for better productivity and minimize waste.

How can I optimize my print settings for DTF printing using the Gangsheet Builder?

To optimize your print settings for DTF printing, ensure you select the appropriate DPI (usually between 300-600 DPI) based on your printer’s capabilities. It’s also essential to choose the right color profiles and set up the ink types correctly. This will allow for vibrant, high-quality prints when using the DTF Gangsheet Builder.

What are the benefits of using a Gangsheet Builder software in custom apparel printing?

Using Gangsheet Builder software, like the DTF Gangsheet Builder, offers numerous benefits in custom apparel printing, including reduced material waste by fitting multiple designs into one transfer, increased efficiency by printing multiple designs simultaneously, and lower overall costs which help small businesses scale their operations.

What should I consider when choosing software for the DTF Gangsheet Builder?

When selecting software for the DTF Gangsheet Builder, consider compatibility with your printer, ease of use, available features for design manipulation, and the ability to import high-resolution images. Popular choices include Adobe Photoshop, CorelDRAW, and any specialized DTF printing software provided with your printer.

How do I prepare my designs for the DTF transfer process using the Gangsheet Builder?

To prepare your designs for the DTF transfer process, start by selecting high-resolution images and adjusting them in graphic design software to match the desired fabric color and size. Once imported into the DTF Gangsheet Builder, arrange these designs to maximize space, ensuring they are positioned for optimal heat pressing results.

What resources can help me master the DTF Gangsheet Builder and DTF printing?

To master the DTF Gangsheet Builder and DTF printing, utilize online resources such as YouTube tutorials, expert blogs like Printful and Transfer Express, and community forums like r/DTFprinting. These platforms provide valuable tips, illustrations, and troubleshooting advice to enhance your skills.

| Key Point | Description |

|---|---|

| Introduction to DTF Printing | DTF (Direct-to-Film) printing is an innovative technique simplifying custom apparel production. |

| Benefits of DTF Printing | Offers vibrant colors and durability, making prints resistant to fading and cracking. |

| Importance of Gangsheet Builder | Optimizes the printing process, reduces waste, and increases productivity by allowing multiple designs on one transfer sheet. |

| Step 1: Design Preparation | Prepare high-resolution images and ensure proper artwork specifications. |

| Step 2: Choosing Software | Utilize software like Photoshop or CorelDRAW for effective gangsheet design. |

| Step 3: Loading Images | Import and arrange images to maximize the space on the gangsheet. |

| Step 4: Print Settings | Set the correct DPI and color profiles for optimal print quality. |

| Step 5: Printing Process | Ensure printer is compatible and set up correctly for DTF printing. |

| Step 6: Post-Printing | Cut gang sheets into designs and apply with heat press under proper conditions. |

| Community and Resources | Engage with online communities and resources for support and troubleshooting advice. |

Summary

DTF Gangsheet Builder is an essential tool that empowers users to efficiently create vibrant and high-quality apparel prints. By mastering the intricacies of the DTF Gangsheet Builder, you can streamline your printing process, reduce material waste, and ultimately enhance productivity. This guide not only details the steps necessary for effective use but also highlights the benefits and community resources available to support your DTF printing journey. Embrace the capabilities of the DTF Gangsheet Builder and start producing stunning, professional-quality designs today.