DTF transfer by size is a foundational concept that turns digital designs into wearable art with the right scale. Whether you’re printing a tiny logo on a sleeve or a full-back graphic on a hoodie, getting the size right yields crisp, professional results. In DTF workflows, the transfer size shapes not only visual impact but also color accuracy, print speed, and durability. This article shows how DTF transfer size guide, DTF print scale, sizing DTF transfers, DTF printing for large formats, and DTF transfer optimization interrelate to deliver a clean, market-ready result. By planning the design for the final print size and then optimizing the file for the garment, you create a repeatable, scalable process.

From an LSI perspective, size-aware printing—often described in practice as DTF transfer by size—frames the project around the final print area, margins, and bleed rather than forcing a fixed template. Think in terms of scalable transfers, where print area, substrate, and heat-press settings vary with garment type but maintain consistent color and edge integrity. Alternative terminology like garment-specific sizing, artwork scaling, and large-format compatibility helps teams communicate expectations and streamline production. By treating scale as a design parameter rather than an afterthought, you align creative intent with practical constraints. Ultimately, this approach supports repeatable results across pocket prints, chest logos, and back panels while preserving visual fidelity.

DTF transfer by size: A foundation for scalable apparel printing

DTF transfer by size anchors your entire workflow in the final garment dimensions, guiding artwork, equipment choice, and heat-press technique toward a single objective: the right scale. By adopting a size-first mindset, you plan for margins, bleed, and surface area before a single color is printed. This approach reduces guesswork and helps you translate digital designs into wearable art with confidence. In practice, you’ll see how phrases like DTF transfer size guide and DTF print scale become actionable steps rather than abstract concepts, improving predictability across orders.

With the right size strategy, color accuracy and durability are easier to manage. This is where DTF transfer optimization comes into play: adapting ink density and color profiles to each garment size, from pocket logos to full-back graphics. Thinking in size also speeds up production, because it minimizes late-stage rework and ensures consistent adhesion across substrates. In addition, the process aligns with DTF printing for large formats by establishing clear expectations about print area, viewing distance, and edge safety that apply whether you print small details or expansive canvases.

DTF transfer size guide: aligning artwork with garment surfaces

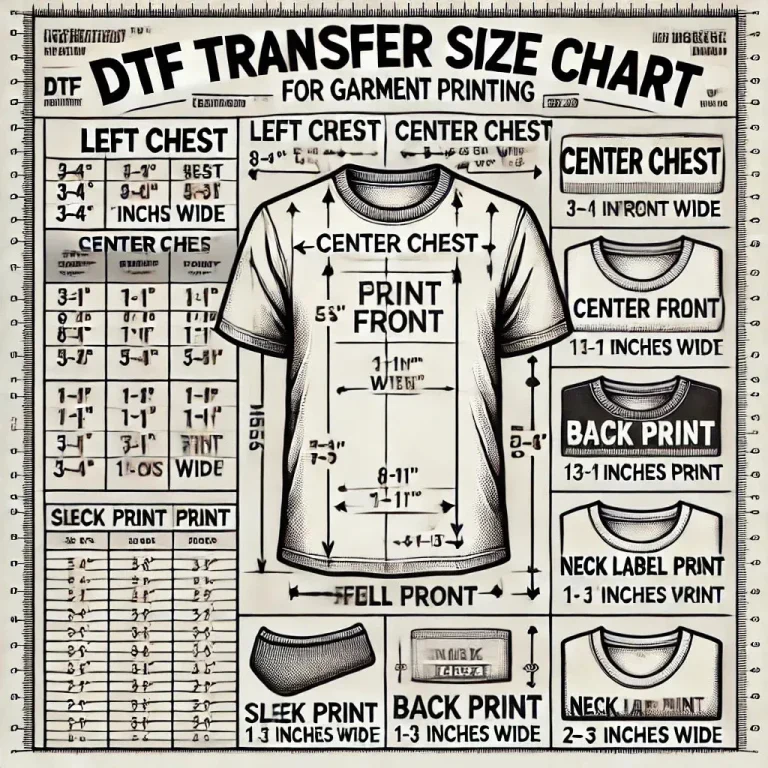

Using a dedicated DTF transfer size guide helps you map target areas (pocket, chest, sleeve, back) to specific pixel budgets and print resolutions. Start by defining the garment surface and then move to margins, safe zones, and overall composition, ensuring the design breathes at its intended size. When you reference a size guide during design, you avoid unnecessary cropping and distortion, preserving the integrity of typography and fine lines.

Developing size-aware variants from a single master design becomes practical when you design with scalable assets. Vector logos and scalable type keep edges clean as you resize across items such as children’s tees, hoodies, or jackets. This practice ties into DTF print scale, which describes how resolution and viewing distance change with size, ensuring your layout remains impactful from a distance and up close.

DTF print scale: optimizing resolution from pocket to back print

DTF print scale describes how we adjust resolution to maintain sharp detail across sizes. For small prints, aim for around 300 PPI at the final size; for larger formats, 150–200 PPI can be sufficient when paired with careful upscaling and vector elements. This balance preserves crisp edges while keeping file sizes reasonable and throughput efficient, aligning with practical guidance from the size-focused workflow.

Aspect ratio and edge treatment become more critical as you scale up. Maintaining the original composition helps prevent distortion on curved surfaces like sleeves or shoulders, and applying vector artwork for logos ensures clean curves when scaled. Addressing these concerns early reduces the need for redesign later and complements the broader theme of size-aware DTF workflows, including considerations for large-format prints.

Sizing DTF transfers: a practical workflow from concept to final transfer at scale

A formal sizing workflow starts with defining the target size or garment area and proceeds through aspect ratio assessment, margins, and bleed, then to the required print resolution and color alignment. This sequence keeps you from chasing last-minute adjustments and ensures scalable outcomes, whether you’re producing a dozen hoodies or a thousand tote bags. Naming this process explicitly as sizing DTF transfers helps teams standardize expectations and measure progress against size milestones.

From there, prepare test prints and adjust based on measured results. Early decisions about final size reduce surprises during production and facilitate batching of multiple sizes from a single master design. The approach dovetails with DTF transfer optimization by focusing on consistent ink usage, reliable adhesion, and uniform heat application across different surface areas.

DTF printing for large formats: ensuring quality on back panels and sleeves

Large-format DTF printing presents unique challenges in heat, pressure, and film handling. Large transfers require uniform heat distribution over a bigger area and sometimes longer dwell times to activate the adhesive fully, which you can plan for in advance. This is where practical techniques—such as platen adjustments, calibrated dwell times, and preheating—ensure back panels and sleeve wraps print with consistent depth and color.

Color management and substrate compatibility become more complex at scale. Calibrating printer profiles for each fabric family and testing across white, light gray, black, and colored garments helps you predict color shifts at large sizes. By treating large formats with the same rigor as smaller runs, you realize the benefits of DTF transfer optimization across diverse products.

DTF transfer optimization: color management, margins, and batch consistency

DTF transfer optimization centers on delivering faithful hues, smooth graduations, and crisp edges across sizes. Start with calibrated profiles for key fabrics, then validate color on representative base colors to anticipate how the transfer behaves as size grows. Consistent margins and centered designs further contribute to a premium, repeatable result across batches.

Quality control becomes a constant practice: mockups with exact dimensions, color-block test strips, and checks for seam-edge adhesion all reduce the risk of large-scale failures. Establish a standard, single-size test protocol for different products, and maintain a stable material stock and equipment settings to ensure dependable outcomes from pocket logos to full-back canvases.

Frequently Asked Questions

What is DTF transfer by size and why is it important across garment areas?

DTF transfer by size is planning and executing designs based on the final print area on the garment, not a fixed template. It matters because size influences visual impact, color density, print speed, and adhesion—from tiny pocket prints to full-back graphics. Use a DTF transfer size guide to keep scale consistent across products and formats, including large formats.

How can I apply a DTF transfer size guide to planning pocket logos vs back panel designs?

Start with the target size for each area, then assess aspect ratio and composition. Establish safe margins and bleed, convert artwork to the required print resolution, and verify color alignment and substrate compatibility. This workflow benefits from DTF transfer optimization to maintain consistency as you scale designs from small pockets to large back panels.

What resolution and print scale should I use when sizing DTF transfers?

For small to medium sizes, aim for 300 PPI at the final print size. For large formats, 200–300 PPI is often sufficient depending on viewing distance; use vector art for logos and type to preserve edges. Align your settings with the DTF print scale to balance detail, speed, and file manageability.

How do I manage color and substrate variations when sizing DTF transfers for different fabric colors?

Calibrate printer profiles for key fabrics you serve and test color on white, light gray, black, and colored fabrics to understand size-related shifts. Consider underbase needs for dark garments and adjust ink density accordingly. This is where DTF transfer optimization plays a crucial role in preserving color fidelity across sizes.

What heat press considerations come with large-format DTF transfers compared to small ones?

Large transfers require more uniform heat and pressure over the entire area, often necessitating longer dwell times and careful alignment. Preheat the garment, use an even-pressure platform, and plan longer press windows for large formats to ensure complete adhesion and edge integrity.

What are common sizing pitfalls and QC checks in DTF transfers by size?

Watch for missed margins, crop distortions, color bleed, and poor adhesion at seams. QC steps include mockups with exact dimensions, scale test strips with representative colors, verifying centering, and confirming edge sharpness on curved surfaces. Following a DTF transfer size guide helps standardize checks and reduce batch-to-batch variation.

| Aspect | Key Point | Practical Details / Notes |

|---|---|---|

| Size-first mindset | Plan the design for final print size; define target surface area (pocket, chest, back) and safe margins/bleed | Aligns artwork, equipment, and heat-press practice to the right scale |

| Sizing workflow steps | Steps: define target size; assess aspect ratio; margins/bleed; convert to required resolution; verify color; test print | From concept to scalable variants that stay consistent across products |

| Design prep: DPI, resolution, aspect ratio | Aim for 300 PPI final size for small/med; 150–200 PPI for very large; use vector for logos; manage aspect ratios to avoid distortion | Edge crispness and crop-line prevention |

| Color management & substrates | Calibrate printer profiles for fabrics; test on white, light gray, black, and colored fabrics; adjust ink density by size | Be mindful of fabric stretch and base color effects on color accuracy |

| Printing, curing, and heat press by size | Use even heat/pressure; preheat; adjust dwell time by size; monitor ambient conditions | Large transfers require longer windows; ensure adhesion across edges |

| Quality control & pitfalls | Mockups with exact dimensions; color test strips; check symmetry/centering; verify crisp edges | Avoid cropping, color bleed, poor adhesion, batch inconsistencies with standardized size tests |

| Case studies | Pocket logo (2×2 inches); Chest print (4×6 inches); Full back (12×16 inches) | Demonstrates size-specific strategies and validation across examples |

Summary

DTF transfer by size is a foundational approach that ensures artwork scales correctly across garments, from tiny pocket accents to bold full-back graphics. Embracing a size-first mindset helps you plan margins, bleeds, and print resolution early, aligning design intent with production realities. By following a structured sizing workflow—defining the target size, assessing aspect ratio, establishing safe margins and bleed, converting to the required print resolution, and verifying color and adhesion—you can reproduce consistent results across multiple garments and formats. Thoughtful consideration of DPI, aspect ratio, color management, substrate differences, and heat-press variables minimizes surprises and reduces waste. With proper QC and documented size-focused procedures, your DTF projects become scalable, repeatable, and marketable.