DTF transfer by size plays a crucial role in the art of Direct-to-Film (DTF) printing, especially for beginners aiming to achieve stunning results on various fabrics. Understanding the nuances of size adjustments is key to making your designs stand out, ensuring they are neither too overwhelming nor too subtle for the intended apparel. This guide delves into the essential DTF printing techniques, providing insights on how to DTF print more effectively while keeping your projects cost-effective and visually appealing. Whether you’re working on kids’ clothing or large adult sizes, mastering the principles of DTF for beginners will enable you to navigate your fabric printing journey with ease. With the right practices and attentiveness to detail, you’ll be able to create vibrant designs that leave a lasting impression.

When it comes to fabric printing, utilizing Direct-to-Film (DTF) transfers based on the dimensions of your designs is essential for success. This innovative printing method allows users to create custom graphics on a variety of textiles, making it an excellent choice for both hobbyists and professionals alike. Understanding how to adjust sizes appropriately in DTF is vital, as it directly impacts the visual appeal of the final product. Beginners often seek guidance on best DTF practices to achieve high-quality prints without compromising on design integrity. This exploration into sizing dynamics aims to equip you with the knowledge to enhance your fabric printing projects.

Understanding DTF Printing Techniques

DTF printing techniques have revolutionized the fabric printing industry by providing a versatile and effective way to reproduce vibrant designs. Unlike traditional methods, DTF utilizes special films and adhesives that ensure the ink adheres firmly to various fabric surfaces, including cotton, polyester, and blends. This technology facilitates intricate designs with high color fidelity, making it popular among both amateur and professional printers alike.

For beginners, it’s critical to familiarize oneself with DTF printing techniques that include layout preparation, film selection, and heat transfer methods. As you progress, experimenting with different techniques can enhance your printing capabilities, helping you produce stunning results that rival more traditional printing methods. Whether you’re creating custom apparel or unique merchandise, mastering these fundamentals will set you on the path to DTF printing success.

Getting Started with DTF for Beginners

If you’re new to the world of DTF printing, getting started may seem daunting. However, there are ample resources available to ease your learning curve. Online tutorials, beginner-friendly courses, and community forums provide guidance on foundational aspects like choosing the right equipment, setting up your workspace, and selecting materials.

Moreover, understanding the basic principles of DTF for beginners is essential for achieving high-quality prints. As a novice, focus on practicing techniques regularly, including how to DTF print correctly and how to troubleshoot common issues that might arise. With a wealth of knowledge at your fingertips, your confidence and skills in DTF printing will rapidly improve.

Choosing the Right DTF Transfer Sizes

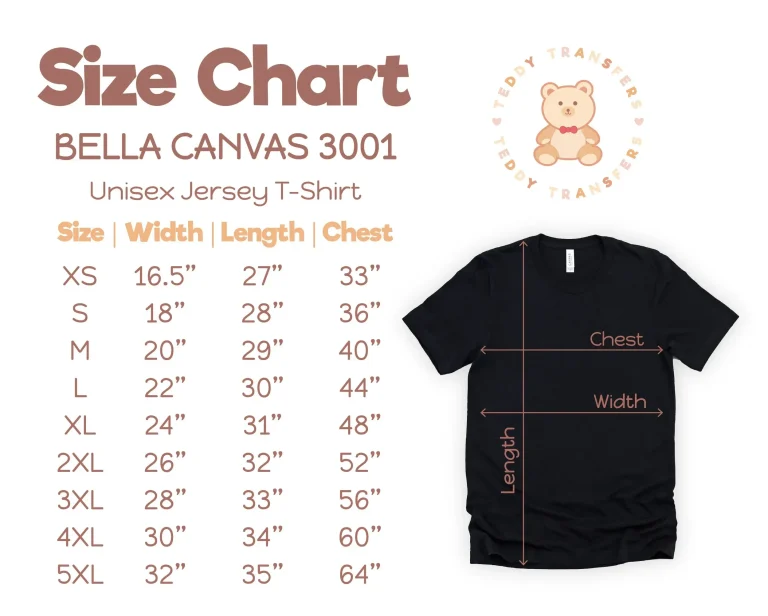

Selecting the appropriate size for your DTF transfers is paramount to achieving professional-quality prints. Different apparel types may require varying transfer sizes, with adult shirts typically featuring designs between 10″ to 15″ in width, while children’s apparel may benefit from smaller designs measuring between 8″ to 10″. By accurately sizing your transfers to match the garment type, you ensure that your designs maintain their aesthetic appeal.

Moreover, understanding size adjustments in DTF transfers not only helps in maintaining the integrity of your artistic vision but also plays a crucial role in effective marketing. A well-sized design can significantly enhance the visibility of your artwork, attracting potential buyers while conveying professionalism. Always visualize potential layouts and be prepared to make adjustments to create the best impact!

Best DTF Practices for Quality Prints

To achieve the highest quality results in your DTF printing endeavors, implementing best practices is crucial. This includes being meticulous about temperature and pressure settings during the heat transfer process. Maintaining optimal conditions usually means adjusting the heat press to a temperature range between 305°F to 320°F. Such attention to detail is essential in ensuring strong adhesion and vibrant colors in your final print.

Additionally, pre-pressing the fabric can make a significant difference in print quality. By eliminating moisture and wrinkles, you facilitate better adhesion of the transfer and enhance overall clarity. Remember that consistent application of these best DTF practices will lead to improved output over time, making your investment in this printing technique worthwhile.

Utilizing Community Resources for DTF Success

As you embark on your DTF printing journey, leveraging community resources can provide invaluable support and enhance your learning experience. Joining online forums or social media groups dedicated to DTF printing can connect you with seasoned professionals who share insights, tips, and troubleshooting strategies. Engaging with a community not only fosters learning but also opens opportunities for collaboration and networking.

Moreover, community resources often include recommendations for suppliers, the best materials for different projects, and advice specific to DTF transfer by size. Many experienced users are eager to share their journey, including challenges they faced with size adjustments, helping beginners navigate potential pitfalls effectively. Embracing these connections will undoubtedly enrich your DTF printing skills.

Final Thoughts on DTF Transfer Techniques

In conclusion, mastering DTF transfer techniques requires practice, patience, and a willingness to learn. As you expand your knowledge on DTF printing, understanding the nuances of design sizing and material selection will empower you to create remarkable pieces that resonate with your audience. Always remember that every successful print starts with a solid foundation.

With this comprehensive guide, as a beginner, you can approach DTF transfer printing with confidence. Embrace the creativity the DTF technology offers, and don’t hesitate to experiment and refine your techniques. By staying connected to resources and communities, you’ll continue to develop your skills, ultimately leading to beautiful printed garments that showcase your unique style.

Frequently Asked Questions

What are the best DTF practices for adjusting transfer sizes?

When adjusting sizes for your DTF transfers, it’s essential to match the design dimensions with the garment’s space. For adult shirts, aim for widths between 10″ to 15″, while children’s apparel typically needs designs that are 8″ to 10″ wide. Additionally, ensure that your heat press accommodates these sizes properly to maintain quality.

How do I size my DTF prints correctly for different garments?

To size your DTF prints effectively, consider the type of garment. For t-shirts, designs should generally range from 10″ to 15″ in width. For smaller items, like children’s clothing, sizes of 8″ to 10″ work best. Always visualize how your design will appear on the garment before finalizing the size.

What materials should I use based on the size of my DTF transfers?

For smaller DTF transfers, standard films are adequate, but for larger designs, opt for thicker DTF films. These maintain better adhesion and offer durability. This choice can significantly enhance the quality of your transfers, especially when dealing with larger sizes.

What temperature settings should I use for DTF transfers of varying sizes?

The optimal temperature for DTF transfers is typically around 305°F to 320°F, regardless of the design size. However, ensure even pressure is applied across larger designs to avoid distortion. Using a temperature gun can help achieve precise settings for every print size.

How do I ensure quality DTF printing when adjusting sizes?

To maintain quality in your DTF printing when adjusting sizes, pre-press the fabric to eliminate moisture and wrinkles, apply sufficient even pressure, and allow the transfer to cool before peeling. These steps are crucial for ensuring adherence and preventing any peeling of larger size transfers.

Are there any resources for beginners to help with DTF transfer sizing?

Yes, beginners can find a variety of resources, such as YouTube tutorials focusing on DTF printing techniques, online courses on platforms like Skillshare or Udemy, and community forums where fellow printers share size adjustment tips for various projects. Engaging with these resources can provide valuable insights for mastering DTF printing.

| Key Points | Details |

|---|---|

| What is DTF Transfer? | An innovative printing process for fabric that uses film coated with adhesive for heat transfer, resulting in vibrant designs. |

| Why Choose DTF Printing? | Versatile on various fabrics, offers bright color quality, and is cost-effective compared to other methods. |

| Choosing the Right Size for Transfers | Adult designs: 10″-15″; Child designs: 8″-10″. Important to visualize final appearance. |

| Material Selection | Standard DTF Film for small designs; thicker films for larger prints to maintain quality. |

| Technical Tips for Quality Transfers | Use correct temperature (305°F to 320°F), pre-press fabrics, and allow cooling before peeling film for durability. |

| Resources for Beginners | YouTube tutorials and online courses on platforms like Skillshare and Udemy. |

| Community Support | Joining online groups and forums for tips on DTF transfer and improving skills. |

Summary

DTF transfer by size is a pivotal concept for mastering fabric printing as a beginner. This process not only involves choosing the right design dimensions based on the intended application, such as adult or children’s apparel, but also requires careful consideration of materials and techniques. With the right approach to sizing, DTF printing can produce eye-catching, durable prints that enhance the appeal of any garment. By understanding these factors, beginners can significantly improve their printing outcomes and fully embrace the creative possibilities that DTF technology offers.